Commercial Single-Ply Membrane Market Worth USD 2303.84M in 2024 - Growth & Trends 2025–2032

Commercial single-ply membranes are roofing materials composed of single layer of synthetic material used in commercial buildings.

“Single-ply membranes are transforming commercial roofing with unmatched energy efficiency, durability, and sustainability for modern infrastructure needs.”

”

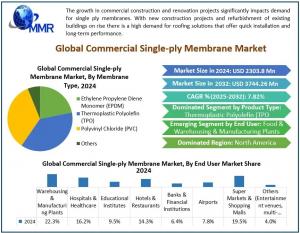

WILMINGTON, DE, UNITED STATES, October 3, 2025 /EINPresswire.com/ -- The Commercial Single-Ply Membrane Market, valued at USD 2303.84M in 2024, is projected to reach USD 3744.26M by 2032 at 7.82% CAGR, driven by TPO, PVC, and EPDM adoption in energy-efficient commercial roofing.— Dharti Raut

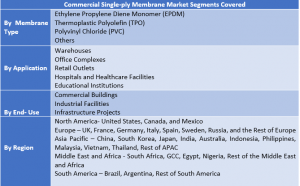

Commercial Single-Ply Membrane Market is witnessing robust expansion, fueled by the rising demand for energy-efficient roofing systems and sustainable construction practices. Single-ply membranes, including TPO, PVC, and EPDM membranes, are increasingly used in commercial roofing applications such as warehouses, retail outlets, healthcare facilities, and industrial buildings due to their durability, cost-effectiveness, and eco-friendly properties. Reflective TPO and PVC roofing solutions can lower cooling costs by up to 20%, while EPDM membranes provide a lifespan of 25–30 years, minimizing maintenance expenses. With more than 50% of new commercial roofs in North America now adopting single-ply membranes and Europe showing a steady 6–7% CAGR in installations, the market is poised for continued growth globally. Supported by regulatory pushes for green building codes and growing investment in infrastructure projects across Asia-Pacific and emerging economies, the market is expected to attract both established players and new entrants focusing on innovative roofing solutions.

𝐈𝐧𝐭𝐞𝐫𝐞𝐬𝐭𝐞𝐝 𝐢𝐧 𝐝𝐞𝐭𝐚𝐢𝐥𝐞𝐝 𝐢𝐧𝐬𝐢𝐠𝐡𝐭𝐬? 𝐈𝐧𝐪𝐮𝐢𝐫𝐞 𝐟𝐨𝐫 𝐚 𝐬𝐚𝐦𝐩𝐥𝐞 𝐫𝐞𝐩𝐨𝐫𝐭 : https://www.maximizemarketresearch.com/request-sample/256671/

Energy Efficiency Meets Durability: Driving the Commercial Single-Ply Membrane Boom

The Commercial Single-Ply Membrane Market is experiencing significant growth, primarily driven by the energy efficiency and cost-saving benefits of single-ply membranes. Products like TPO membranes are highly reflective, reducing up to 80% of solar heat, which lowers air conditioning needs and can cut energy bills by 15–20% annually for commercial property owners. This aligns perfectly with sustainability initiatives and regulatory pressures for greener building practices. The durability of membranes such as PVC and EPDM further fuels adoption, as these materials resist harsh weather, UV radiation, and punctures, with average membrane lifespans reaching 25–30 years, ensuring minimal maintenance. Commercial building owners increasingly prefer these solutions for their cost-effective, low-maintenance performance, making them a key driver of market expansion.

Technological Innovations and Green Building Trends Propel Market Growth

Technological advancements are enhancing the performance and appeal of single-ply membranes, making them more attractive to both manufacturers and end users. Innovative systems like IKO InnoviTPO incorporate advanced weathering formulations that increase membrane resilience, while Carlisle’s new wide TPO sheets can reduce installation time by up to 30%, lowering labor costs. Additionally, the growing commercial construction and renovation sector is boosting demand for quick-install, long-lasting roofing solutions, with over 45% of new commercial roofs in North America using single-ply membranes. Sustainability plays a central role, with recyclable TPO and PVC membranes mitigating environmental impact and contributing to urban heat reduction. Stringent building codes further encourage the adoption of single-ply membranes, as these products meet high standards for energy efficiency, fire resistance, and durability, cementing their position as a preferred choice in modern commercial roofing.

Segment Spotlight: How Membrane Types Are Shaping Roofing Choices

Market segmentation highlights the distinct advantages of each membrane type. TPO and PVC membranes, with their reflective surfaces reducing building cooling costs by up to 20%, are increasingly preferred in regions with high solar exposure. EPDM membranes, representing approximately 30% of single-ply usage in North America, are prized for their flexibility and resistance to extreme weather conditions. The choice of membrane type depends not only on performance but also on installation speed, maintenance requirements, and roof complexity.

Commercial roofing systems utilize membranes across applications such as warehouses, retail outlets, hospitals, and educational facilities, each benefiting from tailored solutions. As companies adopt green building practices and comply with stringent energy codes, these versatile, sustainable, and durable membranes solidify their position as essential components in modern commercial roofing projects.

Regional Insights: Where Commercial Single-Ply Membranes Are Making the Biggest Impact

Regional demand for single-ply membranes varies by market maturity and construction trends. In North America, single-ply roofing is a standard choice for over 50% of commercial buildings, largely due to energy-saving mandates and resilient weather conditions. Europe, with its focus on sustainability, has seen a 3-year CAGR of 6–7% in commercial membrane installations, with TPO and PVC leading adoption.

Asia-Pacific represents a rapidly growing market segment. Increasing investments in industrial facilities, office complexes, and retail developments have made TPO and EPDM membranes highly sought after. With governments encouraging green building practices, single-ply membranes are becoming a preferred choice in urban centers like Shanghai, Mumbai, and Tokyo. Latin America and the Middle East are also showing promising growth due to expanding commercial construction projects and infrastructure upgrades.

Recent Developments in Commercial Single-Ply Membrane Market

January 2025 – Advanced TPO Membranes for Cold Weather: Manufacturers introduced new TPO membrane formulations with enhanced weldability and flexibility, enabling efficient installation even in regions with harsh winters. This innovation is designed to reduce installation delays and expand the usability of TPO membranes in colder climates.

July 2024 – Carlisle Companies Acquires Henry Company: Carlisle completed the acquisition of Henry Company, strengthening its position in the commercial roofing segment. This strategic move expanded Carlisle’s portfolio of commercial roofing membranes and improved its ability to serve diverse markets with innovative roofing solutions.

Key Trends Shaping the Market

Growing Demand for Energy-Efficient Roofing Solutions: Single-ply membranes such as TPO and PVC roofing are increasingly favoured for their high reflectivity, which can reduce building cooling costs by up to 20%, aligning with sustainability initiatives in the global construction sector.

Shift Toward Sustainable & Eco-Friendly Materials: Manufacturers are focusing on eco-friendly and recyclable membranes, addressing global sustainability goals. With rising pressure from regulations and green building certifications, demand for sustainable commercial roofing membranes is accelerating worldwide.

Top Roofing Companies and Strategies Driving Market Leadership

Major players in the Commercial Single-Ply Membrane Market, including GAF, Firestone Building Products, Sika, and Carlisle, are leveraging advanced technologies and innovative products to stay ahead. TPO and PVC membranes remain the focus of new product launches, with companies introducing features that improve durability and reduce maintenance. Notably, GAF’s reflective roofing solutions and Sika’s EPDM innovations have contributed to over 20% energy savings for commercial clients, enhancing the appeal of sustainable roofing.

Strategic mergers and acquisitions and regional expansions allow these companies to strengthen their global presence, while smaller manufacturers focus on customized solutions and eco-friendly materials to capture local demand. With commercial construction growing and regulations emphasizing energy efficiency, these strategies help companies enhance brand recognition, capture market opportunities, and increase their market share in a highly competitive environment.

𝐅𝐨𝐫 𝐟𝐮𝐥𝐥 𝐚𝐜𝐜𝐞𝐬𝐬 𝐭𝐨 𝐭𝐡𝐞 𝐝𝐚𝐭𝐚, 𝐫𝐞𝐪𝐮𝐞𝐬𝐭 𝐚 𝐬𝐚𝐦𝐩𝐥𝐞 𝐫𝐞𝐩𝐨𝐫𝐭 𝐧𝐨𝐰 : https://www.maximizemarketresearch.com/request-sample/256671/

Commercial Single-ply Membrane Market Key Players

North America

Carlisle (United States)

GAF Materials Corporation (United States)

Firestone Building Products (United States)

Johns Manville (United States)

Duro-Last (United States)

Owens Corning (United States)

Versico (United States)

Tremco Roofing (United States)

IKO Industries (Canada)

Europe

Sika AG (Switzerland)

Holcim (Switzerland)

Bauder GmbH (Germany)

RENOLIT SE (Germany)

Kingspan Group (Ireland)

Soprema Group (France)

BMI Group (United Kingdom)

Protan AS (Norway)

Asia-Pacific

Oriental Yuhong (China)

TechnoNICOL (Russia)

Hongyuan Waterproof (China)

Jianguo Weiye Waterproof (China)

Goliath (India)

Analyst Recommendation:

Analysts recommend that stakeholders in the commercial single-ply membrane market prioritize energy-efficient roofing solutions such as TPO and PVC membranes to align with global green building standards. Expanding into high-growth regions like Asia-Pacific and leveraging technological innovations will be key strategies for enhancing market share and long-term competitiveness.

Commercial Single-Ply Membrane Market FAQs

Q1. What is single-ply membrane roofing?

A1. Single-ply membrane roofing is a lightweight, single-layer roofing system made from TPO, PVC or EPDM that provides waterproofing, energy savings and long life for commercial and industrial roofs.

Q2. What are the benefits of TPO and EPDM roofing?

A2. TPO delivers high reflectivity and energy savings (up to ~20% cooling reduction); EPDM offers long durability (25–30 years) and superior resistance to UV and weathering.

Q3. How much does commercial single-ply roofing cost?

A3. Installed commercial single-ply systems vary by region and roof complexity, but lifecycle costs are typically lower than built-up roofs because of reduced maintenance and energy savings.

Q4. How long do single-ply membranes last?

A4. PVC and EPDM commonly last 25–30 years; TPO typically lasts 20–25 years depending on installation quality and maintenance.

Related Reports:

Commercial Single-ply Membrane Market: https://www.maximizemarketresearch.com/market-report/commercial-single-ply-membrane-market/256671/

Maximize Market Research is launching a subscription model for data and analysis in the

Chemicals and Materials market: https://www.mmrstatistics.com/markets/728/topic/358/construction-materials

About Us :

Maximize Market Research is one of the fastest-growing market research and business consulting firms serving clients globally. Our revenue impact and focused growth-driven research initiatives make us a proud partner of majority of the Fortune 500 companies. We have a diversified portfolio and serve a variety of industries such as IT & telecom, chemical, food & beverage, aerospace & defense, healthcare and others.

Contact Us :

MAXIMIZE MARKET RESEARCH PVT. LTD.

2nd Floor, Navale IT park Phase 3,

Pune Banglore Highway, Narhe

Pune, Maharashtra 411041, India.

+91 9607365656

Lumawant Godage

MAXIMIZE MARKET RESEARCH PVT. LTD.

+ +91 96073 65656

email us here

Visit us on social media:

LinkedIn

Instagram

Facebook

X

Legal Disclaimer:

EIN Presswire provides this news content "as is" without warranty of any kind. We do not accept any responsibility or liability for the accuracy, content, images, videos, licenses, completeness, legality, or reliability of the information contained in this article. If you have any complaints or copyright issues related to this article, kindly contact the author above.