CMP Slurry Additives Market Forecast to Surpass USD 2.17 Billion by 2036, Driven by Semiconductor Planarization Demands

Advanced semiconductor nodes, logic and foundry growth, and tighter defect control requirements underpin long-term market expansion

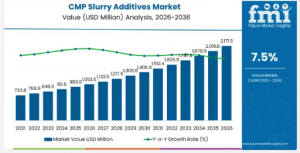

NEWARK, DE, UNITED STATES, January 19, 2026 /EINPresswire.com/ -- The global CMP slurry additives market, a critical component of semiconductor manufacturing materials, is projected to experience sustained growth over the next decade. Market value is expected to increase from USD 1,053.5 million in 2026 to USD 2,171.3 million by 2036, representing a compound annual growth rate (CAGR) of 7.5% during the forecast period.

CMP (chemical mechanical planarization) slurry additives are essential to wafer fabrication processes, enabling precise surface leveling, controlled material removal, and defect mitigation across increasingly complex semiconductor architectures. As logic, memory, and advanced packaging technologies evolve, demand for specialized slurry chemistries continues to rise across global fabrication facilities.

Why CMP Slurry Additives Are Gaining Strategic Importance

The growth of the CMP slurry additives market is closely tied to shrinking device geometries, multilayer interconnect complexity, and rising yield sensitivity in semiconductor production. Advanced manufacturing nodes require exceptionally tight planarity control to ensure device reliability and performance.

Slurry additives—including dispersants, stabilizers, oxidizers, corrosion inhibitors, and pH control agents—are engineered to regulate particle behavior, optimize removal rates, and reduce surface defects such as scratching, erosion, and dishing. These functions are increasingly critical as manufacturers adopt multi-patterning techniques and higher-density designs.

CMP additives are no longer considered auxiliary consumables; they are yield-critical inputs directly influencing throughput efficiency and final device quality.

Market Segmentation Highlights

Dispersants and Stabilizers Lead by Function

By additive function, dispersants and stabilizers represent the largest segment, accounting for approximately 34% of total market share. Their dominance reflects the industry’s emphasis on slurry stability and uniform abrasive distribution during extended polishing cycles, particularly for advanced interconnect layers.

Logic and Foundry Applications Dominate Demand

By application, logic and foundry manufacturing accounts for roughly 40% of total market demand. CMP is used extensively throughout logic device fabrication, from front-end transistor formation to back-end interconnect processing. High wafer volumes and advanced node adoption in foundry environments further amplify additive consumption.

Regional Outlook: Asia Pacific at the Forefront

Regional growth patterns reflect differences in semiconductor fabrication capacity, node transition pace, and investment intensity:

• China is expected to record the fastest growth, with a projected 8.7% CAGR, supported by expanding domestic semiconductor production and materials localization initiatives.

• Brazil is forecast to grow at 8.3% CAGR, driven by gradual expansion in electronics manufacturing and specialty semiconductor applications.

• United States growth is projected at 7.2% CAGR, underpinned by increased investments in domestic fabrication and advanced process technologies.

• Germany is expected to grow at 7.1% CAGR, supported by demand from automotive, industrial, and power semiconductor segments.

• South Korea is projected to expand at 6.7% CAGR, reflecting continued strength in memory manufacturing and defect-sensitive processes.

Asia Pacific remains the largest and most influential regional market, while North America and Europe continue to prioritize high-performance planarization and advanced qualification standards.

Competitive Landscape and Industry Challenges

The CMP slurry additives market is characterized by high technical barriers to entry, including stringent purity requirements, long qualification timelines, and tight contamination control standards. Suppliers must demonstrate consistent performance across multiple process nodes before adoption at scale.

The competitive environment favors established materials manufacturers with deep expertise in semiconductor process integration, formulation stability, and defect control. Competition is increasingly centered on performance reliability and process compatibility rather than pricing alone.

Market Outlook

As semiconductor manufacturers advance toward next-generation logic devices, heterogeneous integration, and increasingly complex interconnect structures, CMP slurry additives will remain essential to achieving required surface quality and yield targets.

Ongoing global fab expansion, combined with rising technical demands at advanced nodes, positions the CMP slurry additives market as a strategically important segment within the semiconductor materials ecosystem over the coming decade.

Request for Sample Report | Customize Report |purchase Full Report - https://www.futuremarketinsights.com/reports/sample/rep-gb-31471

Explore More Related Studies Published by FMI Research:

Dimethylolpropionic Acid (DMPA) Market https://www.futuremarketinsights.com/reports/dimethylolpropionic-acid-market

Bamboo Market https://www.futuremarketinsights.com/reports/bamboos-market

Bentonite Market https://www.futuremarketinsights.com/reports/bentonite-market

About Future Market Insights (FMI)

Future Market Insights, Inc. (FMI) is an ESOMAR-certified, ISO 9001:2015 market research and consulting organization, trusted by Fortune 500 clients and global enterprises. With operations in the U.S., UK, India, and Dubai, FMI provides data-backed insights and strategic intelligence across 30+ industries and 1200 markets worldwide.

Why FMI: https://www.futuremarketinsights.com/why-fmi

Sudip Saha

Future Market Insights Inc.

+1 347-918-3531

rahul.singh@futuremarketinsights.com

Legal Disclaimer:

EIN Presswire provides this news content "as is" without warranty of any kind. We do not accept any responsibility or liability for the accuracy, content, images, videos, licenses, completeness, legality, or reliability of the information contained in this article. If you have any complaints or copyright issues related to this article, kindly contact the author above.